Team Members: Will Johnston and Janith Godakawela

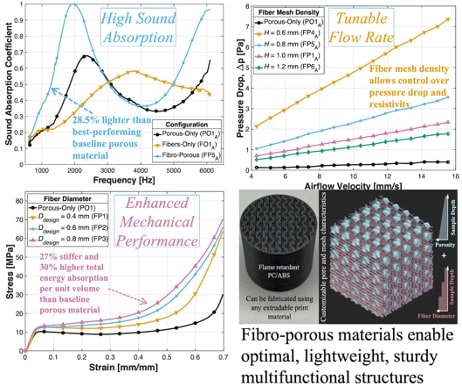

The advancements in additive manufacturing have significantly improved sound absorption capabilities through fibrous structures. However, despite these improvements, fibrous structures still face challenges related to stiffness and multifunctionality. On the other hand, open-celled porous structures like triply periodic minimal surfaces (TPMS) offer promising mechanical properties due to their cubic symmetry and uniform stress distribution. These lattice structures demonstrate superior mechanical performance, including stiffness, energy absorption, and noise reduction.

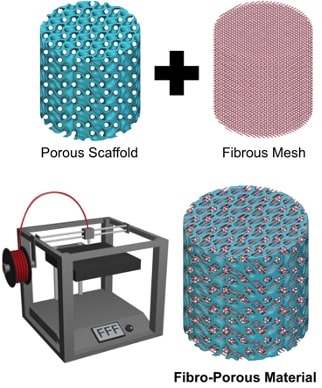

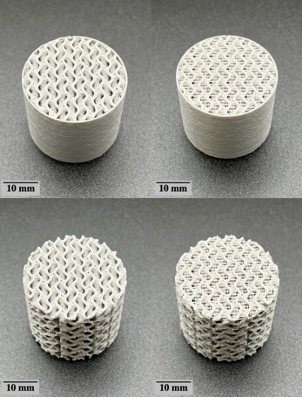

Nevertheless, manufacturing TPMS with small pores presents certain obstacles such as increased weight and flow restriction. To tackle these challenges, we introduce our novel technology: Fibro-Porous materials. Leveraging our expertise in 3D printing fibers, we overlay these fibers onto larger pores to effectively reduce their size. This innovative approach results in a lightweight solution for reducing pore size without significantly altering the flow path. Consequently, stiffness, multifunctionality, and mechanical properties are significantly improved.

Our research delves into understanding printing imperfections and evaluating various factors such as structural density, fiber thickness, sound absorption, flow resistance, and energy absorption. These investigations shed light on the immense potential of Fibro-Porous materials, promising advancements in aerospace, server technology, and automotive engineering.

Publications:

- Johnston, W., Kankanamalage, P. G., Gatti, C., Keshavanarayana, S., & Sharma, B. (2024, January). Fibro-Porous Materials: 3D Printed Hybrid Acoustical Materials for Multifunctional Applications (Submitted).

- Johnston, W., Kankanamalage, P. G., & Sharma, B. (2021, August). 3D printed multifunctional, load-bearing, low-frequency sound absorbers. In INTER-NOISE and NOISE-CON Congress and Conference Proceedings(Vol. 263, No. 1, pp. 5605-5610). Institute of Noise Control Engineering.

- Johnston, W., Kankanamalage, P. G., Pathak, S., Drouin, M., & Sharma, B. (2021). 3D printed fibrous porous structures with enhanced noise reduction properties. The Journal of the Acoustical Society of America, 150(4_Supplement), A308-A308.

- Johnston, W., & Sharma, B. (2021). Additive manufacturing of fibrous sound absorbers. Additive Manufacturing, 41, 101984.